2023CHINACOAT | Jinmao Titanium Liu Zhi: Deepening the Foundation of Green Development and Sharing New Achievements in Titanium Dioxide Technology

Release time:

2023-11-23

Hui Zheng Information: As enterprises continue to pursue sustainability and digitalization, the coatings industry is undergoing many changes. CHINACOAT, as one of the largest coatings exhibitions in Asia, has a total exhibition area of over 90,000 square meters, with more than 1,300 exhibitors from 33 countries/regions showcasing competitive raw materials and production equipment for the entire line of coatings, as well as other cutting-edge technologies and formulations to a global audience.

As a large manufacturing enterprise specializing in the production of titanium dioxide, as well as industrial sulfuric acid, polyferric sulfate, red iron oxide, and ferrous phosphate, Guangxi Jinmao Titanium Co., Ltd. (hereinafter referred to as "Jinmao Titanium") has been deeply engaged in the titanium dioxide field for many years. At the 2023 CHINACOAT, Jinmao Titanium showcased multiple high-quality titanium dioxide products, demonstrating its technological innovation capabilities and enhancing its brand influence through exchanges and sharing with industry professionals on technology and products. This also increased cooperation opportunities with industry clients and provided new development ideas to help coating enterprises smoothly respond to industrial changes.

It is understood that Jinmao Titanium was established in 2003 and completed its share reform in September 2022, officially becoming a joint-stock limited company. Jinmao Titanium covers an area of about 400,000 square meters, with more than 1,300 employees, located in Teng County, Guangxi, known as the "Hometown of Titanium Dioxide." The transportation conditions in the area are very convenient, with a comprehensive transportation network advantage of rail, road, air, and water. Some production raw materials are sourced locally, giving the products comprehensive advantages in resources, transportation, costs, and market competition. The company's products are widely used in coatings, inks, rubber, plastics, chemical fibers, papermaking, ceramics, and denitration fields, and are well-received by customers in Asia, Europe, Africa, and America.

At the same time, Jinmao Titanium has six well-equipped production lines for titanium dioxide, capable of producing various types of anatase and rutile titanium dioxide according to market demand, with a production capacity of 160,000 tons/year, ranking among the top in the country for anatase titanium dioxide production. It is reported that Jinmao Titanium has also built supporting production facilities for an annual output of 500,000 tons of industrial sulfuric acid and 300,000 tons of polyferric sulfate.

At this exhibition, Jinmao Titanium mainly showcased products such as pigment titanium dioxide, enamel titanium dioxide, rutile plastic-specific titanium dioxide, decolorized pure titanium, metallurgical titanium dioxide, and chemical fiber titanium dioxide. With excellent performance, beautiful appearance, and innovative technology, these products attracted the attention of many professional customers at the exhibition, laying a solid foundation for Jinmao Titanium to further expand its market and helping to enhance its competitiveness and influence in the industry.

Regarding the changes in the coatings field this year and how Jinmao Titanium is responding to these changes, Liu Zhi, the deputy general manager of Jinmao Titanium, stated in an interview with Hui Zheng Information at the exhibition that the coatings industry and the titanium dioxide industry have always been closely related, and the consumption of titanium dioxide in the coatings industry is significant. Therefore, the development of the coatings industry is closely linked to the development of the titanium dioxide industry. In recent years, the coatings industry has also faced constraints due to the downturn in the real estate industry, with raw material prices remaining high, increasing cost pressure, and making production and operation difficult. In light of this, Jinmao Titanium has implemented relevant countermeasures in areas such as "improving quality, reducing costs, and increasing efficiency" and optimizing product structure.

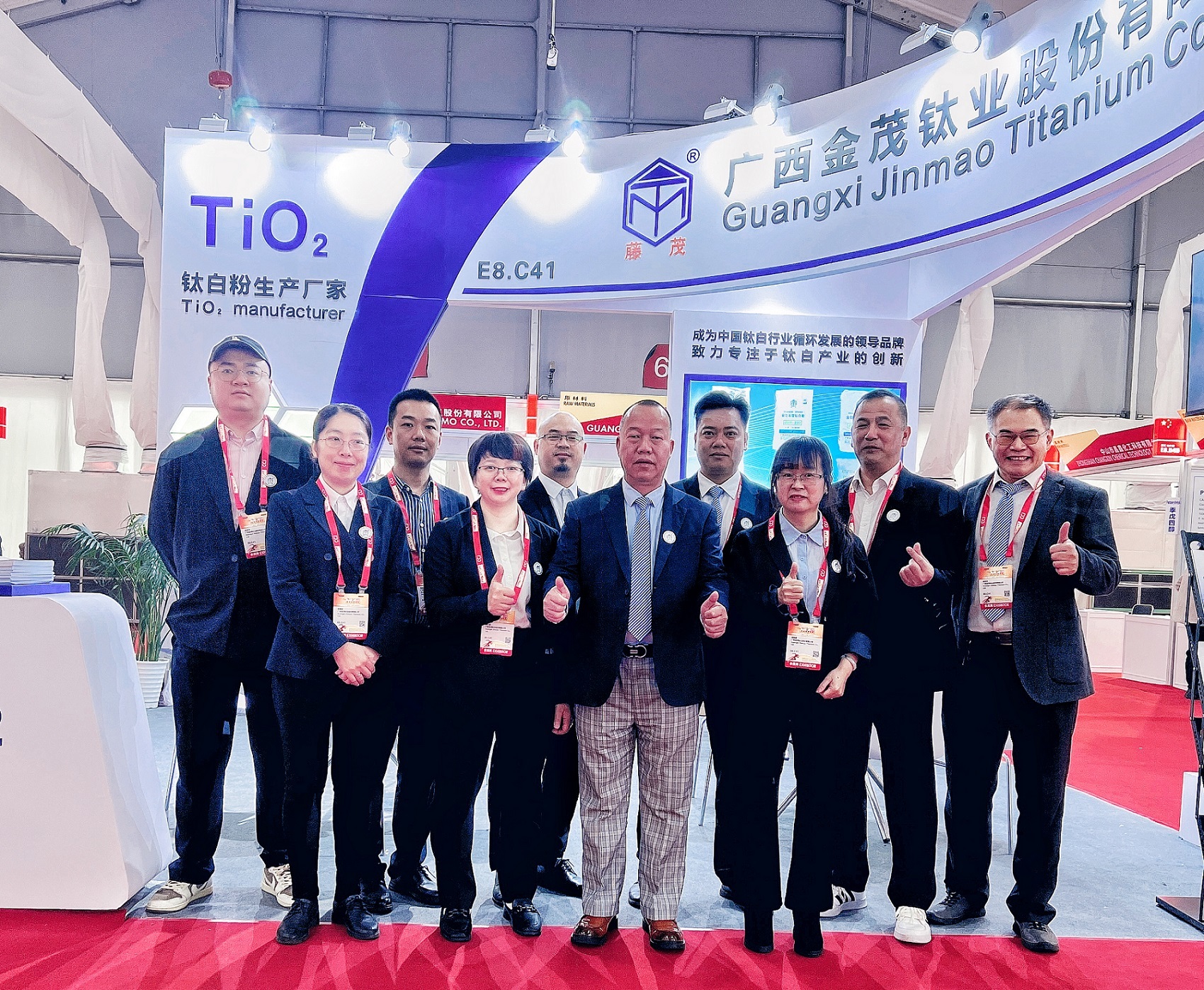

(Middle) Liu Zhi, Deputy General Manager of Jinmao Titanium

In the current situation of unstable titanium dioxide market conditions and intense market competition, Jinmao Titanium is primarily focusing on new product development, process technology, and equipment upgrades as key initiatives. Additionally, it is addressing energy conservation and consumption reduction, as well as automation control. Currently, the company has a good order status, with operating rates and production operations maintaining a controllable and positive trend. There are also many high-value-added new products being launched, which greatly avoids vicious competition due to homogenization. With the diversification of product varieties, Jinmao Titanium's market awareness and overall competitiveness have been comprehensively enhanced.

Regarding the uncertain future and unknowns, Liu Zhi stated that since its establishment, Jinmao Titanium has fully utilized its comprehensive advantages in resources, quality, costs, and market competition, adhering to a practical approach to "rolling development." After years of hard work, the company has initially developed into a large-scale, diversified product structure, circular economy-oriented, resource-saving, and environmentally friendly green chemical comprehensive enterprise, laying a solid foundation for becoming a leading brand enterprise in the domestic titanium industry for circular economy development.

To better utilize the titanium dioxide by-product ferrous sulfate, Jinmao Titanium has now entered the new energy field, using ferrous sulfate as the iron source for producing ferrous phosphate, and is planning to build a ferrous phosphate production project, which is currently progressing steadily. Additionally, to better implement circular economy and economies of scale, as well as comprehensive development advantages in technology, brand, location, and market, the company plans to build a new full-process acid-titanium co-production line for titanium dioxide in the new materials park within the next 3 to 5 years.

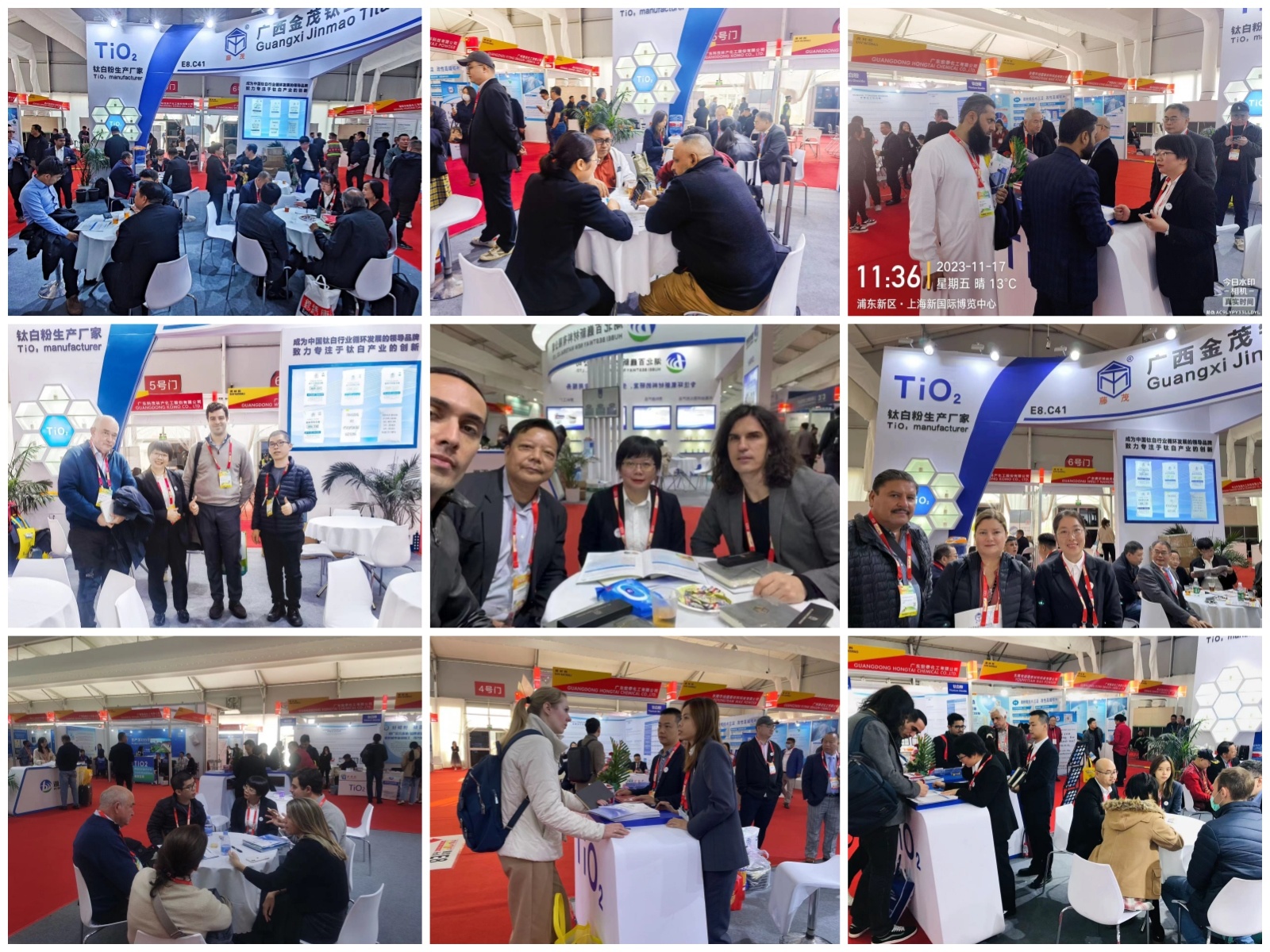

Jinmao Titanium booth foreign interaction

2023 is a year of significant opportunities, challenges, and key developments in the history of titanium dioxide. Jinmao Titanium, in light of new business opportunities and the subsequent development trends of the titanium dioxide market, is facing the impacts of the post-pandemic era. Liu Zhi stated that Jinmao Titanium will continue to uphold the spirit of overcoming difficulties, seeking innovation and change, and pragmatically working hard. In the face of uncertainty, it will cultivate new opportunities and open new situations. The specific countermeasures are mainly reflected in the following five aspects:

1. Further accelerate the investment ratio in technological transformation, optimize product structure, and produce market-oriented, high-value-added seasonal products (decolorized pure titanium, chemical fiber titanium dioxide, calcium-neutralized titanium dioxide, metallurgical titanium dioxide, rutile crude products JMR-220, JMR-230, JMR-2366, etc.) to meet the diverse needs of the market.

2. Strengthen the control of "improving quality and reducing costs, increasing sources and saving expenses," especially in strengthening the control of product quality, costs (procurement costs and production costs), and yield, further enhancing the brand awareness of the company's products and overall market competitiveness.

3. Further strengthen internal control work within the enterprise, especially in areas such as system formulation, process design and optimization, and performance evaluation, to lay a solid foundation for standardizing enterprise management and implementing the preparation for listing.

4. Attach importance to environmental protection and the comprehensive utilization of resources. Currently, Jinmao Titanium is equipped with a complete "three wastes" treatment system and a national environmental protection online automatic monitoring and control system. In terms of the comprehensive utilization of the three wastes, Jinmao Titanium is deeply engaged, continuously increasing the investment in safety and environmental protection, ensuring that the three wastes meet discharge standards, practicing the development concept of "circular economy," and following the path of "scientific development and technological innovation" for green ecological development. This aims to achieve environmentally friendly and clean production while also increasing the added value of by-products, truly realizing the development goal of "treating waste with waste, nurturing waste with waste, turning waste into treasure, and comprehensive utilization." Additionally, it helps to extend the upstream and downstream industrial chain, laying a solid foundation for the company to further achieve safe production, environmentally friendly production, clean production, energy-saving production, and automated production. This will also provide strong momentum for the company's subsequent stable development.

5. Keep pace with the times and enter the new energy field. The company is currently utilizing the comprehensive utilization planning of titanium dioxide by-product ferrous sulfate to construct a phosphate iron project, entering the new energy field and sharing in the industry's development feast. Currently, the phosphate iron project is progressing steadily. Additionally, the company is planning a new project for titanium dioxide and supporting sulfuric acid capacity to enter the new materials park and is preparing for related work.

At the end of the interview, Liu Zhi stated that after years of hard work, Jinmao Titanium's titanium dioxide industry has achieved a certain scale and industry status. The technological innovation in titanium dioxide production and product upgrades has also gained a foothold in the industry. The next development goal is to strengthen, expand, and optimize the titanium dioxide industry. It is believed that with the strong support of governments at all levels and the joint efforts of all employees of the company, following the development idea of "strengthening leading enterprises and enhancing industries" in the district, city, and county, we will work steadily, innovate actively, implement bold policies, and truly achieve the production and operation goals of "everyone bears the heavy burden, everyone has targets" and "break through conventions and overcome time limits." We will overcome the adverse effects brought by the post-pandemic era and further integrate resources and leverage advantages, ensuring that Jinmao Titanium's titanium dioxide industry becomes a highly influential green chemical comprehensive industry in the domestic and international titanium sector, characterized by circular economy, resource conservation, and environmental cleanliness, as well as a production base for titanium dioxide, a technology innovation base, a circular economy demonstration base, and a production-education-research demonstration base.

Looking back, the growth of Jinmao Titanium has been infused with the collective wisdom and efforts of everyone. This care and support will transform into the driving force for Jinmao Titanium's progress, while also inspiring and urging all Jinmao people to bravely climb the peaks of the titanium industry.

Change with the times, act according to the situation, and pursue endless progress. Looking to the future, although the tasks are daunting, the mission remains glorious. Jinmao Titanium will start from a new starting point, full of new fighting spirit, fulfill new missions, establish a new image, lead the market with technology, work pragmatically, strive for new breakthroughs, and at the same time, Jinmao will also promote the coating industry towards green and high-quality development with high-quality and high-performance products, contributing to the prosperity and development of the industry, and together stepping towards new brilliance!!!

| recommend News

The China Coatings Exhibition successfully concluded from November 25 to November 27, 2025, at the Shanghai New International Expo Center. As the industry's annual highlight event, this year's exhibition brought together high-quality resources and cutting-edge trends from both upstream and downstream sectors. Guangxi Jinmao Titanium Co., Ltd. showcased its presence at E6.B06, where it joined industry peers to witness the latest developments in coatings and raw materials, and reaffirmed its commitment to "stability and reliability" in every face-to-face interaction.

2025-12-02

Meeting in Turkey | Jinmao Titanium Meets You at Plast Eurasia 2025

Plast Eurasia Istanbul 2025 will be held from December 3 to 6 in Istanbul, Turkey. Guangxi Jinmao Titanium Co., Ltd. will be showcasing its team at Hall 1, 113D3, where you can meet face-to-face with partners from the Eurasian region and share best practices in maintaining stable quality and reliable delivery. You're welcome to visit us for discussions and exchanges.

2025-12-03

Jinmao Titanium to Showcase at "Ruplastica 2026"

Guangxi Jinmao Titanium Co., Ltd. successfully concluded its participation in "RUPLASTICA 2026, the International Plastics and Rubber Exhibition in Russia." During the five-day exhibition, we engaged in in-depth exchanges with professional visitors and partners from Russia, the CIS, Europe, and other regions. At the event, we showcased functional materials and efficiency-enhancing solutions tailored for plastic and plastic-steel applications, garnering widespread attention and positive feedback.

2026-02-02

According to the information from the Guangxi Teng County Media Center on June 28, 2022, Guangxi Jinmao Titanium Co., Ltd. was established in 1970 and is a joint-stock private enterprise specializing in the production and operation of titanium dioxide in China.

2023-11-27

Hui Zheng Information: As enterprises continue to pursue sustainability and digitalization, the coatings industry is undergoing many transformations. CHINACOAT, as one of the largest coating exhibitions in Asia, has a total exhibition area of over 90,000 square meters this year, with more than 1,300 exhibitors from 33 countries/regions showcasing competitive raw materials and production equipment for the entire line of coatings, as well as other related cutting-edge technologies and formulations.

2023-11-23

On June 18, 2022, Professor Peng Changhong from Central South University and Deputy Dean He Fang from the School of Chemical and Biological Engineering at Guilin University of Technology led a team of expert professors to visit Jinmao Company to guide the industrialization construction work of iron phosphate.

2023-11-27